Leading pickleball paddle factory

POM, a brand under Dongguan POM Sporting Goods Co., Ltd., was established in 2015 and is headquartered in Dongguan, China.

Since its establishment, we have been deeply involved in the field of pickleball paddle customization

a creative team of experienced designers who keep designing the latest pickleball paddlefor you

In terms of craftsmanship, we always adhere to the attitude of striving for excellence,ensure product quality

High-quality service is the key to win the trust of customers. We have established a complete service system

About POM

pickleball paddle Factory

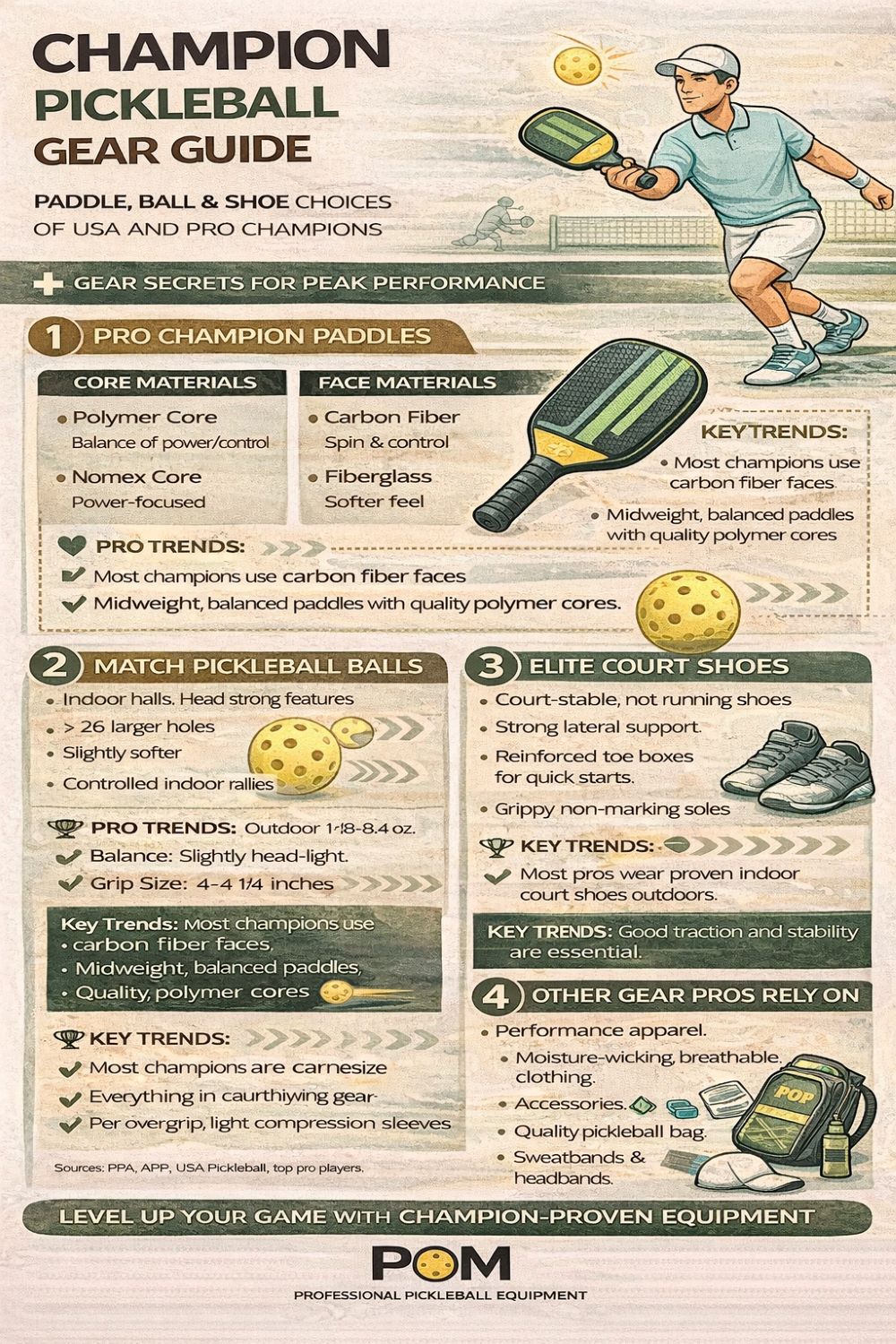

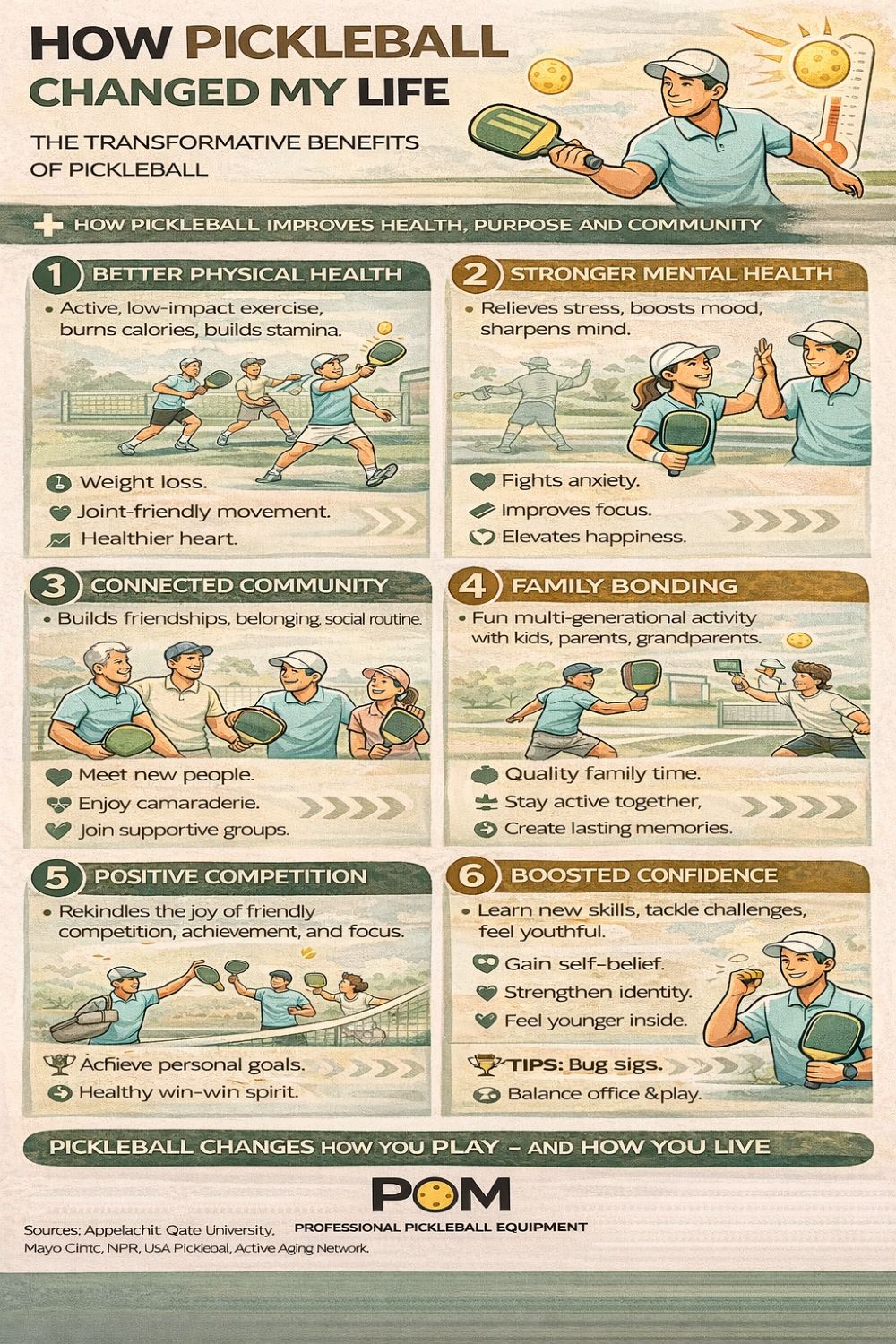

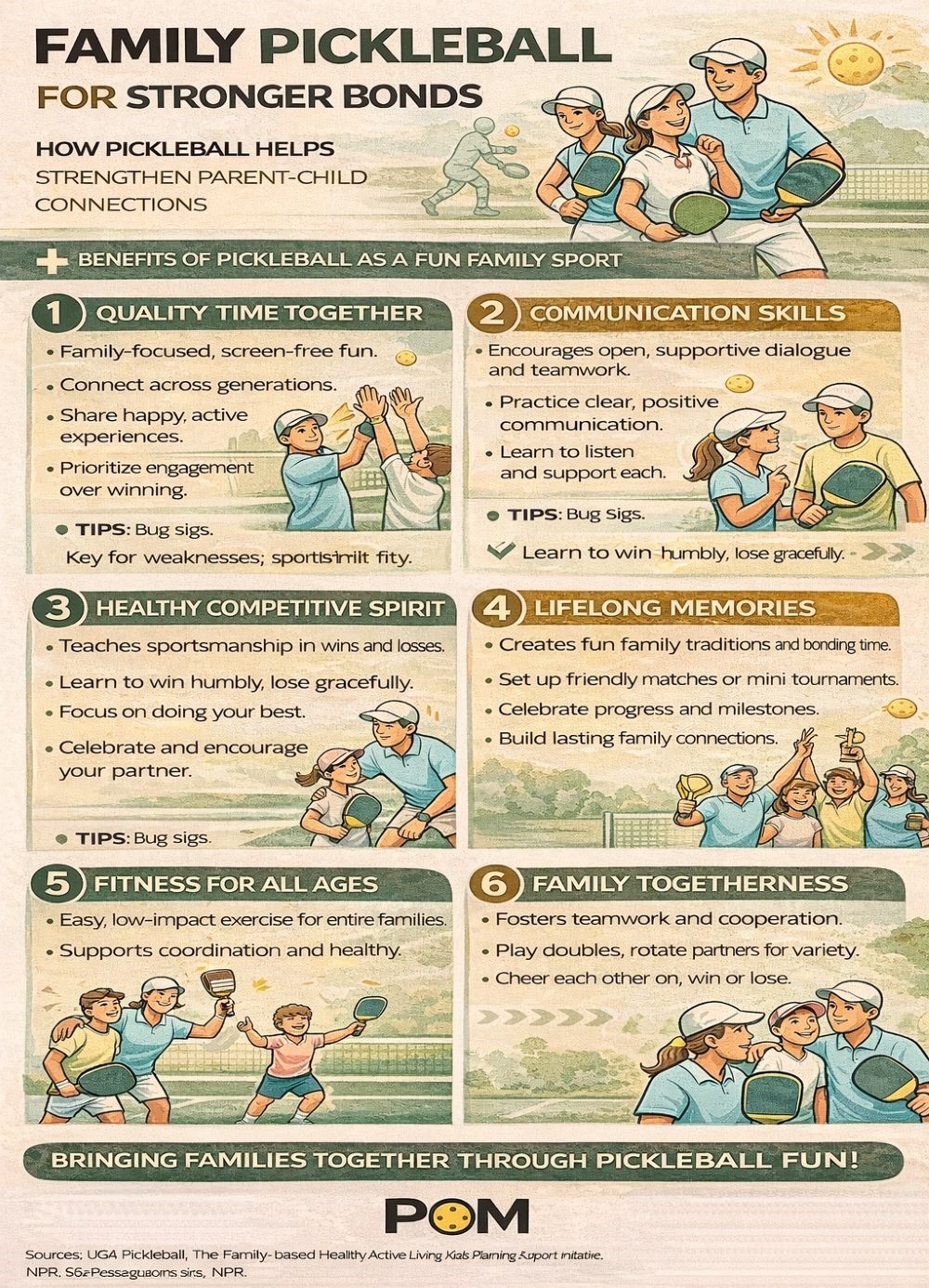

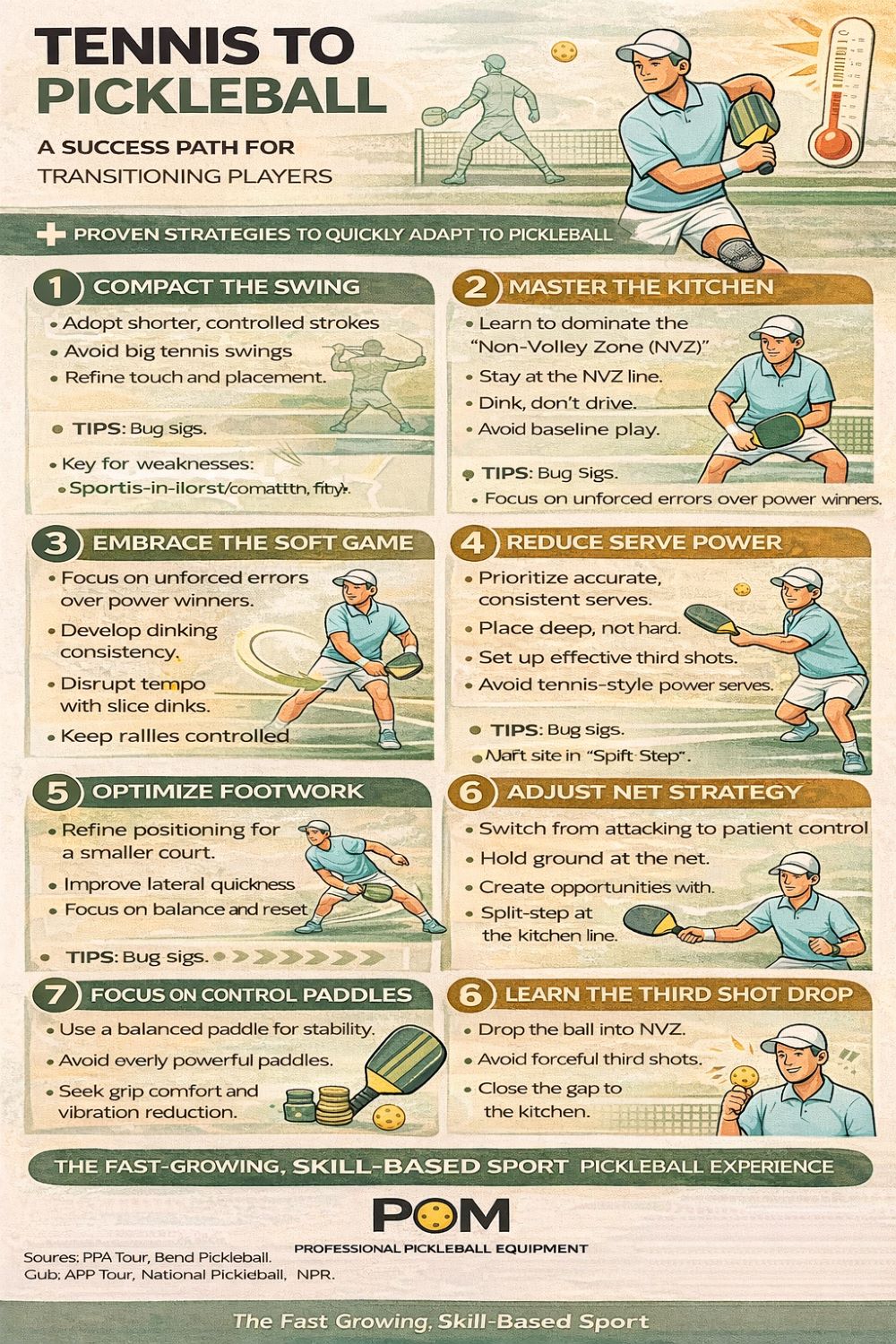

POM, a brand under Dongguan POM Sports Goods Co., Ltd., was established in 2015 and is headquartered in Dongguan, China. It is a large-scale industrial company integrating the design, production, manufacturing, and sales of peakball equipment. POM’s main products include: fiberglass peakball paddles, carbon fiber peakball paddles, 12K carbon fiber peakball rackets, T700 carbon fiber peakball rackets, 26-hole peakballs, 40-hole peakballs, peakball bags, portable peakball nets, and other accessories. Our diverse product range caters to different consumer groups and multi-level needs, and is widely applicable to various peakball events, daily fitness activities, and other sports.

Modern pickleball paddle Factory

To meet the growing demand for orders, we expanded the factory area.6000㎡area include workshop, office, dormitory, sports center…

Our pickleball paddle factory has fully implemented 6S management and established various management systems, processes, standards and tools.

Mechanized workshop

Now our pickleball paddle factory is located in the industrial town of Gaobu, Dongguan City, with a construction area of 6,000 square meters of standard workshops, international leading level of automatic production lines and computerized automatic processing equipment, more than 50 trained and skilled employees, more than 20 professional designers, engineers and technical personnel and more than 10 industry experienced quality management and inspection personnel, which is a modern OEM ODM pickleball paddle and accessories manufacturer with research and development. design, production and sales.

After 10+ years of development, POM has become one of the leading enterprises in the pickleball equipment industry. Our products cover a variety of series such as carbon fiber pickleball paddle,glass fiber pickleball paddle,pickleball balls,pickleball nets, etc. With excellent product performance and quality service, we have established long-term and stable cooperative relations with many well-known brands, and our products are exported to domestic and foreign markets.

office

We have an efficient service team to solve customers’ problems at any time.

Whether it is pre-sales consultation and customized solutions, or after-sales service, we have standardized processes.

10 years Professional pickleball paddle Factory

manufacturing Process

How we work

POM pickleball paddle factory advantages

Strict quality control system & professional quality team, professional and experienced staff, 10+ years Of pickleball paddle manufacturing experience.

Comprehensive PVC extrusion product range, high quality and reliable products, provide the best price for all kinds of custom extrusion profiles.

Our R&D department has complete process of making drawings into reality. We also improve your product design based on our experience.

Nothing can be achieved if we don’t implement precise management. We ensure that every order is completed smoothly

We’ll receive your feedback to make us a better supplier. We’ll deal with problems till you feel satisfied.Effective Communication

Delivery On Time

As the best PVC extrusion factory,we have sufficient manufacturing capacity, big orders won’t beat us, we can deliver order in time.