pickleball paddle manufacturing capacity

Experience our comprehensive pickleball paddle manufacturing capabilities, meticulously crafted to meet your unique needs. Our expertise spans OEM/ODM pickleball equipments... Trust us to bring your productions to life.

Equipment

20+ Professional equipments

Design

50+ Engineers & skilled workers

Manufactured

6000 m²+ Modern Factory area

Years Experience

Happy Customers

Designing Projects

Modern factory

manufacturing Process

How we work

How do we focus on further improving product quality control and make efforts to this end.

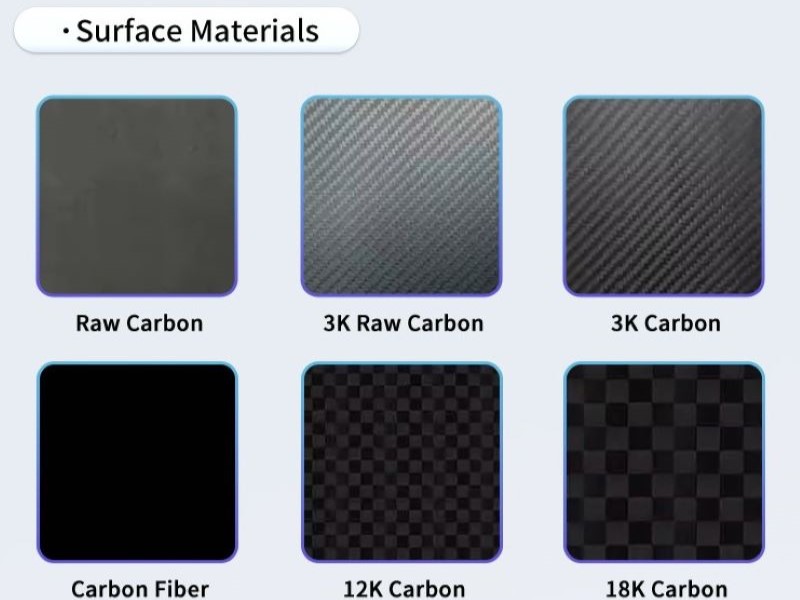

Good raw materials are one of the key factors to ensure pickleall paddles and we have been strictly reviewing it,ensure the high quality of materials

Close partnerships with dozens of of reliable material suppliers guarantee constant access to quality materials.We have strict standards

We hold the ISO 9001:2015 certification, which stands as evidence of our unwavering commitment to quality.

Various testing machines, like tensile machine,and 3D scanners. We know the importance of equipment.

Our strict commitment to quality control regulations ensures quality is maintained production.

Get comprehensive quality reports from our in-house quality team or third-party labs for every products.

Products

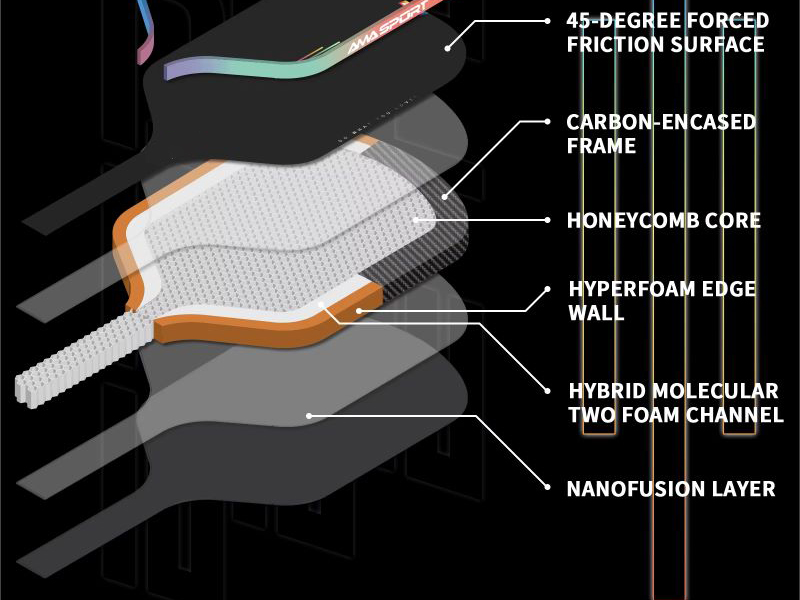

Let's see pickleball paddles we can do

Get in touch

As a 10+ years custom pickleball paddle manufacturer, we have a team of skilled engineers ready to support you in your product development journey from prototyping to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote as soon as possible.